Evaluation of fillers in paper and board within seconds: non-destructive, accurate and reliable

This article was published in Spanish language in the El Papel Magazine, Issue April, May, June 2020 beginning on page 22

This article was published in Spanish language in the El Papel Magazine, Issue April, May, June 2020 beginning on page 22

With the emtec ACA Ash Content Analyzer, a new way to measure the total mineral filler content as well as the percentage content of the individual filler components of paper and board, is finally introduced to the pulp and paper industry worldwide.

With the Ash Content Analyzer (ACA), emtec Electronic aims to overcome the disadvantages of the traditional combustion method. The innovative lab instrument replaces combustion with x-ray technology, enabling the non-destructive measurement of individual mineral fillers in paper and board shown as combined or separate results. Time consuming test procedures are no longer necessary, because the data are available for e.g. process optimization in less than one minute.

Common practice in pulp, paper and board industry

In the pulp, paper and board industry, mineral fillers are used to influence the characteristics of the paper, either internally or on the surface. Typical fillers are for example calcium carbonate, kaolin, titanium dioxide, talcum and barium white. If recycled pulp is used in the production, an additional element of uncertainty are the fillers, which are already included in the recycled material. To optimize the necessary additional amount of fillers used in the production, the existing amount of fillers within the waste paper needs to be known. If fillers can be added optimally, the quality of the finished product increases.

Traditional combustion method

The traditional combustion method is a tool in the pulp, paper and board industry to get information about the mineral filler content in paper and board, but this method can only provide limited information and only to a certain level of accuracy (approx. 5 percent deviation). Additionally, the combustion is energy and time consuming (it takes three to seven hours), and it depends on the operator and the state of the sample (e.g. moisture).

According to ISO and TAPPI, two standard procedures exist:

| paper is burned at 525°: | result: total ash content as a summarized value |

| paper is burned at 900°: | result: calcium carbonate and kaolin + titanium dioxide |

emtec ACA Ash Content Analyzer

Compared to the combustion method, the emtec ACA Ash Content Analyzer has a lot of advantages: the result is available after a pprox. 30 to 60 seconds, it is independent from environmental and human influences (e.g. operator, sample moisture) and the results are very accurate (only up to 0,3 percent deviation). Additionally, the device measures the total filler content as well as the single components of the included mineral fillers in percent. One measurement detects the single fillers calcium carbonate, kaolin and talcum, titanium dioxide, iron oxide, barium white and others. Furthermore, the ACA needs less space in the laboratory, could be easily transported and is quickly installed. That the measurement does not destroy the sample is a further advantage and is especially important in cases of banknotes, security paper or objects of historical literature and art.

pprox. 30 to 60 seconds, it is independent from environmental and human influences (e.g. operator, sample moisture) and the results are very accurate (only up to 0,3 percent deviation). Additionally, the device measures the total filler content as well as the single components of the included mineral fillers in percent. One measurement detects the single fillers calcium carbonate, kaolin and talcum, titanium dioxide, iron oxide, barium white and others. Furthermore, the ACA needs less space in the laboratory, could be easily transported and is quickly installed. That the measurement does not destroy the sample is a further advantage and is especially important in cases of banknotes, security paper or objects of historical literature and art.

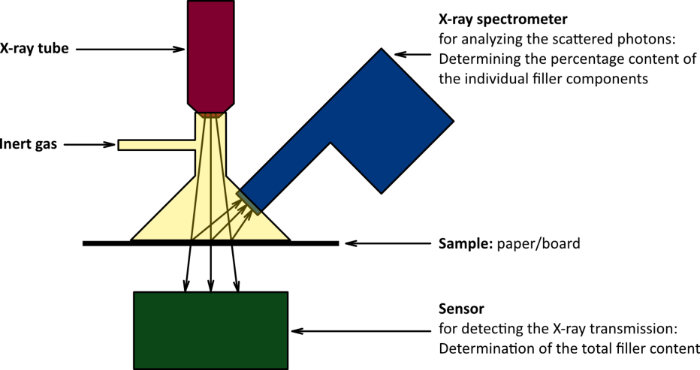

The ACA measuring principle

The measuring method of the emtec ACA is based on the combination of X-ray fluorescence analysis and the transmission method. First, the captured X-ray fluorescence spectra are qualitatively evaluated, and afterwards, they are quantitatively determined concerning the concentration of the detected filler components. The signal peaks are converted using complex mathematical functions (algorithms) in the corresponding concentrations. The picture to the left illustrates the measuring principle. When the measurement starts, the area around the paper sample gets locked by a cylinder and the area is flushed with helium gas to ensure that the argon content of the surrounding air has no impact to the result.

The measuring method of the emtec ACA is based on the combination of X-ray fluorescence analysis and the transmission method. First, the captured X-ray fluorescence spectra are qualitatively evaluated, and afterwards, they are quantitatively determined concerning the concentration of the detected filler components. The signal peaks are converted using complex mathematical functions (algorithms) in the corresponding concentrations. The picture to the left illustrates the measuring principle. When the measurement starts, the area around the paper sample gets locked by a cylinder and the area is flushed with helium gas to ensure that the argon content of the surrounding air has no impact to the result.

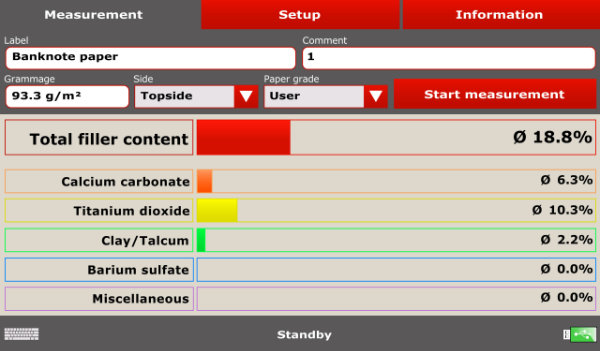

The ACA results and data analysis

The ACA is characterized by an especially simple handling. After inserting the sample and entering a label, the grammage and optionally a comment by the help of an integrated touch screen, the measurement can be started. After about 30 seconds the total filler content and the percentage of each mineral filler, for example, calcium carbonate, titanium dioxide, kaolin, talcum and barium white are displayed (see picture to the right).

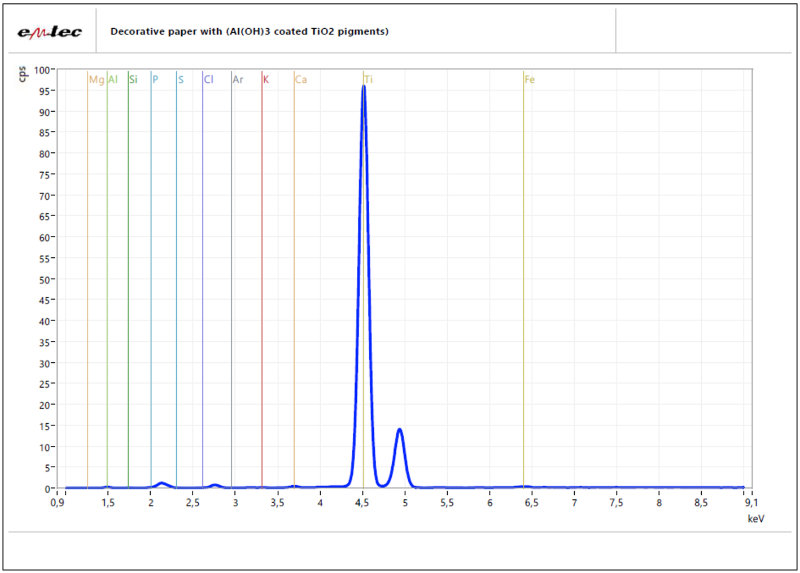

If the device is connected to a PC or laptop, the emtec measurement software shows the whole spectrum of the sample components (see picture below). Proper trained users can find a lot of information in those spectra. The main point of view is the relation between the different elements to each other. A certain relation between aluminum and silicium for example is a sign for kaolin. If in the spectrum is only aluminum, but no silicium peak, it is very likely that the aluminum is coming from the coated titanium dioxide pigments, which have been used. This example already shows the importance of the information provided by the emtec ACA, even though the information is not given directly.

Conclusion

To be able to optimize the product quality and the consumption of fillers, a deep knowledge of the fillers, which are used in the respective paper production process is necessary. Finally, with the emtec ACA Ash Content Analyzer a device is introduced to the pulp and paper industry in 2020, which helps to get important information about the presence and concentration of fillers, which are used in the paper production.

related articles

- ACA - Ash Content Analyzer

- New innovations along with well-tried at PTS Coating Symposium

- Emtec test devices allow a detailed evaluation of paper and board characteristics

- The emtec ACA Ash Content Analyzer provides valuable information about the total mineral filler content and the percentage content of the individual filler components in paper and board.

- emtec Electronic with its innovations at the IMPS 2019 in Munich